What’s a library of physical and cognitive demands (PCDAs) worth? Many of our clients set out to complete PCDAs, also known in some organizations as Job Demands Analyses, or Physical Demands Descriptions, for all of their jobs. Some clients only complete them as needed. When or why would it be worthwhile to complete an entire “library” of them? (Remember “libraries”? In this case, we mean an electronic library or database of documents.)

What’s a library of physical and cognitive demands (PCDAs) worth? Many of our clients set out to complete PCDAs, also known in some organizations as Job Demands Analyses, or Physical Demands Descriptions, for all of their jobs. Some clients only complete them as needed. When or why would it be worthwhile to complete an entire “library” of them? (Remember “libraries”? In this case, we mean an electronic library or database of documents.)

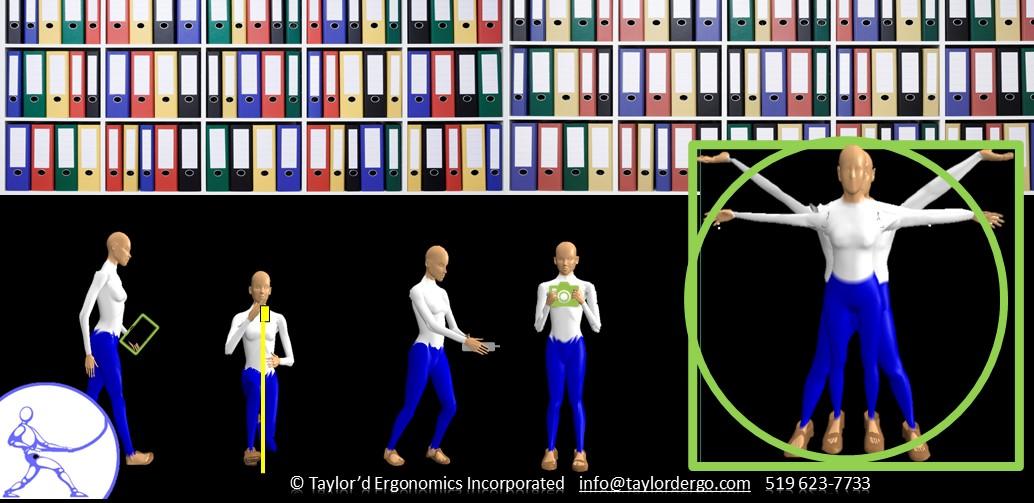

Firstly, what is a PCDA? A PCDA is an objective document that describes the physical and cognitive demands of the job. The PCDA should enable readers to “picture” the job as if they were standing and watching it. It should also provide a deeper understanding of demands that cannot be “seen”, such as how much force is used to push a handle, how repetitively the arm moves, or when the employee is multitasking.

How are PCDAs used, and why would you want a library of them?

- Return-to-work

A PCDA can help with a return-to-work (RTW) case. The document should describe the job requirements in enough detail that the reader can identify which tasks fall within a worker’s specific capabilities. Supervisors or RTW coordinators can use this information to figure out if that job can be modified to accommodate the worker. A worker with a concussion, for example, might not be able to work in a job that exposes the worker to loud noise or bright lights, and might not be up to heavy-duty decision making or multi-tasking. A worker with a left wrist injury might need to be placed in a job that can be done mostly with the right hand. A PCDA can help identify the accommodations (changes) that would allow the worker to get back to work.

If you have a full library of PCDAs, you can also look for other suitable jobs in the department, if the pre-injury job is not suitable.

2. Claims management

When managing injury claims, a PCDA might be used to show the insurer or WSIB that the employer is offering suitable work. A PCDA can also help insurers and the WSIB to better understand the demands of the job that the employee was performing at the time of injury. They can be worth their weight in gold in certain circumstances.

Completing PDCAs on an ad hoc basis works well if you have an ergonomist onsite regularly, or in-house people trained to do PCDAs who are available to drop everything and complete the required assessment immediately. However, PCDAs take time to complete, so you need to be prepared to wait a few days to get an assessment completed. A few days of lost time can incur a significant cost!! If you have a library of PCDAs, the document will be available when you need it.

3. Communicating with health care providers

Doctors, physiotherapists, and other health care providers rarely have the opportunity to see the job that their patient performs; they typically rely on the patient’s description. How many of us can describe how much effort we exert to push a cart, or how frequently we reach forward with the left hand? Sending the PCDA to the health care provider allows that person to better understand how the injury might have happened, and what rehabilitation needs to occur for that worker to successfully return to full duties. This approach is only possible if you have a library of PCDAs ready when the injury occurs!

4. MSD Hazard assessment

When your Joint Health and Safety Committee looks for hazards, they typically walk around with a workplace inspection checklist, looking for green book violations. Musculoskeletal disorder (MSD) hazards can be hard to spot. The PCDA provides a tidy description of all of the tasks performed by the worker, and quantifies the efforts and postures that are required. They make the perfect starting point for a basic hazard assessment. We often do “screening” for MSD hazards after we finish a PCDA, and this screening can feed directly into the JHSC’s process.

If you have a library of PCDAs, you can provide your JHSC with a rich source of data to help them keep your workers safe.

5. Placement and training

A PCDA should communicate job demands visually, in a way that is easy to follow.

If you have PCDAs done for all of your jobs, they can be used as visual aids when posting a job opening, so candidates can understand what they are signing up for. They can also be used by supervisors when training new employees.

6. Job rotation schedules

If you have completed all of the PCDAs for a line or department, you will be able to see which jobs require more manual handling, which are more repetitive for the hands, which require power tool usage, etc. Identifying the differences between jobs is the first step in setting up an effective job rotation schedule. Ideally, workers should rotate from a job that is “hard” for one muscle group to a job that is easier for that muscle group (but possibly hard for another.) In this way, the muscles can recover and avoid fatigue at the end of the day.

So, in summary, a PCDA is useful, but a library is powerful!

If the jobs in your organization don’t change much from year to year, PCDAs can be used for years. When changes occur to jobs, they can be updated. Your library is a big investment at first, but less costly to maintain.

How can a company create a library of PCDAs? So glad you asked. Completing PCDAs is a technical process, so it requires education, training, and experience. PCDAs are documents that require objectivity (measurements), literacy (concise description), photography skills, interpersonal skills (to gain cooperation of workers) and a good report template.

I started out in this field by completing hundreds of PDAs in an assembly environment, and I believe that competency at completing PCDAs creates a stronger foundation for more complex assessments. This has been the case for most of the ergonomists that we’ve mentored over the years; if we ask them to complete a complex ergonomics (risk) assessment before they’ve mastered PCDAs, they struggle to organize the job and identify the important tasks. Novice ergonomists truly benefit from the opportunity to do PCDAs over and over until they are comfortable with interviews, observations, photography, measurements, analysis, and report writing. Mentorship during this process was invaluable to me all those years ago, and continues to be invaluable to them. And while newly-minted ergonomists might think that PCDAs are boring (because they are documenting job demands, rather than leading the charge to improve the job), they quickly find that just “being” in the work environment is challenging and rewarding. The rest will come, and they will be thankful for the solid foundation they gained while doing PCDAs… (Remember back to the novice days in your own career… were you allowed the time and given the mentorship to create a solid foundation?)

The real take-home message for this article is that, because PCDAs are perfect training projects for new ergonomists, clients who want to build a library of PCDAs are a glove-fit with our services during our hiring season. We plan to hire four new grads this summer, and we’re currently looking for placements for them. Our “On-Site Ergo+” program (OSE+) places a novice ergonomist at your site, 1-2 days/week for a year. The mentoring ergonomist trains, supervises, and provides quality control, and may have time to support more advanced “ergonomics” initiatives later in the year. We can populate a significant library over the course of one year, and the cost savings are truly phenomenal. Bonus: OSE+ offers free ergonomics awareness materials, including a monthly bulletin on an ergonomics topic, weekly ergo thoughts, twice yearly ergo contests with draw prizes, and more.

Contact carrie@taylordergo.com for a custom proposal.