If you’re part of the “industrial sector” then you may be aware that the Ontario Ministry of Labour (MOL) is planning another focus on material handling, for September 14-October 23 this year. Now is the time to proactively address this potential hazard. The blitz focus is expected to include:

- Lifting devices

- Manual handling procedure

- Mobile/transport equipment

- Storage systems

- Internal responsibility system

- Worker training

- Workplace supervision

We are able to assist you with all of these priorities, but most clients call us for support with procedures and training aspects.

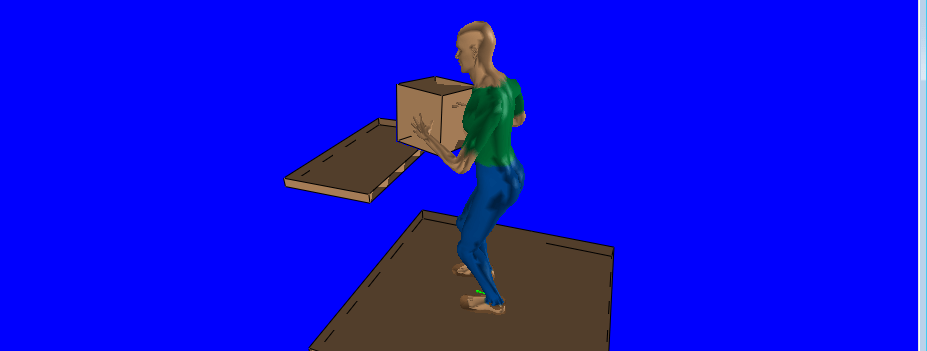

Manual Handling Procedures

If your workers have “options” about how to handle an object, you must ensure that workers are performing “in a manner that prevents MSD injuries…” If they have the option to lift more than they ought to, or to avoid using a lifting device, you should consider control measures to limit these practices, to avoid orders for “supervision to ensure OHSA compliance”. If you need guidance on how much is safe to lift in a certain situation, we can assess the job and provide you with a safe weight limit. (How many parts should this worker carry at a time? How large should this tote be?)

We’ve heard the argument that “devices have been put in place to protect the workers who need it, but if someone doesn’t need it, why should he or she be forced to use it?” Lifting devices sometimes slow workers down, so, given a choice, some workers will avoid using them to save some time. If the device can’t be used at a regular work pace, it needs to be reviewed; safe workers shouldn’t be disadvantaged. We’ve seen situations where the (self-described) stronger workers refuse to use the device, and then end up injured as a reward for their machoism. Talk to your near-retirees about their backs, shoulders, elbows, and knees. They’ll undoubtedly advise younger workers to use whatever assistive devices are provided, so they don’t accumulate as many of the aches and pains that too often accompany retirement from manual work. If the device truly improves safety, it should be used by everyone.

Worker training

Lifting training has been around for at least 30 years, with dismal results. The majority of lost-time injuries recorded by the Workplace Safety and Insurance Board still are back injuries. You can find “lifting training” PowerPoint presentations on the internet, that you might be tempted to roll out as “training”. (Most of these are heavy on the injury stats and anatomy, and light on the practical guidance.) Even if you find a good presentation, or make your own, please think twice about rolling out “training” in presentation format. Effective training should:

- Present effective lifting methods through discussion and demonstration

- Allow participants to practice these lifting methods in a safe environment

- Provide feedback on participants’ lifting performance

- Encourage an understanding of when each method applies (and, just as importantly, when it does not! The golfer’s lift, for example, is perfect for paper clips, but perfectly awful for heavy or awkward packages!)

- Confirm understanding with a test

- Encourage participants to check their techniques back at their jobs (with a checklist, or with the ergonomist checking their performance)

Can lifting training be done online? Could you learn to change a tire by reading about it? We feel that the only way to really learn to do something is by doing it, and having someone confirm that you’re doing it right. That’s pretty hard to arrange without face-to-face contact.

Off-the-shelf training works well when workers are handling boxes, totes, or a variety of objects. However, there’s really no point in teaching a nurse how to lift a box. The methods might apply, but it takes a fair about of imagination to apply them! For example, we teach workers to “lift part of the load at a time”. In other words, take more trips with fewer parts, or move an object by lifting one end and then the other, “jogging” it along. This technique applies to nursing, where employees are encouraged to lift one leg at a time for positioning, or to encourage the patient to support some of his/her own weight. However, health care has its own “language”, and learning is optimized if we can translate ergonomics into the worker’s native tongue!) Similarly, if the workers are consistently handling one type of objects that is particularly awkward (like fridges, or poles), then it makes more sense to customize the training.

If you have lifting devices in place, such as lift tables, hoists, or carts, then the training is an opportunity to ensure that they are being used to their full advantage.

Call us now (519.623.7733) for help in preparing for the fall material handling blitz! You can also get more information on our face-2-face lift training or lifting train-the-trainer workshop on our website.