Why do clients call us? Typically, organizations call us:

- when they need to build a library of physical and cognitive demands analyses

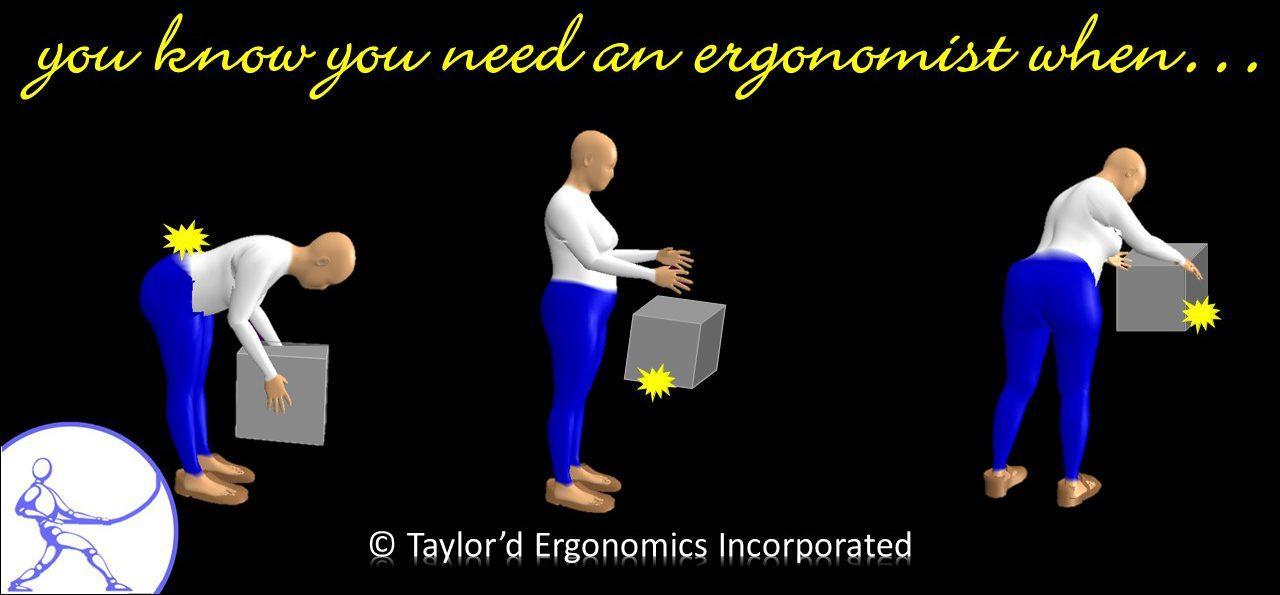

- after employees report discomfort or injury that they attribute to a job

- when the supervisor, HR Manager, JHSC, and Safety Professional are not able to identify a practical solution to the concern

- when disagreement occurs regarding whether there is a significant hazard, or what should be done to mitigate risk

- when the employer needs help to return injured workers to work

For the past 25 years, these have been the most common requests. Increasingly, however, we’re seeing a trend toward more proactive involvement. We’d prefer to be called before equipment presenting strain/sprain injury hazards is brought into the facility. Why? Two reasons:

- Organizations that hire us to do “design reviews” can save money by avoiding employee discomfort and injury.

- It’s less expensive to install a line at the best height, or address reach issues, when the design is on paper than to retrofit it after it is installed.

Pre-start safety reviews are required under legislation, but for many organizations, the PSR’s main goal is to address legislated issues such as pinch points and lock-out.

Strain/sprain injury risk was a common thread on my list of common reasons to call us. Should optimizing comfort and avoiding musculoskeletal injury of our workers be the ultimate goals of ergonomics? Isn’t that what we mean by “fitting the task to the worker”? Not necessarily. There are other indicators, and some of these offer the potential to save even more money than injury prevention. So if your organization doesn’t experience many strain/sprain injuries, don’t dismiss ergonomics!

Employees are more likely to make mistakes, and less likely to give their best performance when they are working in awkward postures or exerting high efforts. This is true in ANY work environment, from office work to tree planting. Any metric that measures human performance can be influenced by ergonomics.

- Customer service reps cannot possibly provide cheerful service if they are uncomfortable and all they can think about is how much they want to get up and move around. They won’t consistently enter data accurately if there is glare on the screen. In this case, the discomfort can simmer for a long time before it’s recognized, but the customer service metrics are affected measurably.

- If the recommended practice for lifting a 100 lb crate is to use 2 people, think about how much time it might take to round up an extra person if that crate needs to be moved near break time. If the 2 people are already tired, what are the chances that the crate might be dropped, damaging the fragile contents?

- If two clips have to be pushed together “just so”, but the worker is tired at the end of the shift, how many more customer returns will be logged?

- If “quality” is valued more than “quantity”, particularly in a self-paced work environment, then employees will slow down when they get uncomfortable. They might never report an injury, and they might never make a mistake, but the potential to improve productivity in these environments is very high.

There is a still a widespread need to do “reactive” ergonomics in most work environments, to gain control of strain/sprain injuries. However, when we come into a facility through the ‘safety’ door, it can be difficult for us to get the data that we need to demonstrate a quality or productivity benefit; I assure you, these benefits are out there. We challenge our clients to look for “baseline” productivity and quality metrics so we can later compare “post-intervention” data. Our optional ergo survey asks about employee perceptions of their own productivity and quality, pre- and post-intervention. It’s surprising, even to me, that most employees report that discomfort significantly affects their output and error rates.

Ergonomists are not trained in school to speak in the languages of quality and productivity, but we are highly trainable. And we have skills that can augment your quality and productivity programs by helping to improve human performance.

So, when do you need an ergonomist? Certainly, if injuries, discomfort, productivity, or quality problems have made their way into your organization, an ergonomist can help. Eventually, we hope you’ll involve us in work design, before the equipment and jobs have been created.