When your mother tells you to “fix your posture”, she is reminding you to sit up tall, keep your shoulders back and your head up. When ergonomists refer to “posture”, we are referring to “body position”. The position of your arms, legs, and body influence how hard you have to work to exert a force. “Awkward posture” is a term that ergonomists use to refer to one of the three main hazards for strain/sprain injuries; an awkward posture is not in an optimal position for the task being completed. (The other two main hazards are force and repetitive/static efforts, which we’ll talk about in another post.) Awkward postures often occur because the workstation does not permit the worker to use the ideal position, and occasionally occur because the worker chooses to use them. The following will help explain what I mean.

Working height matters

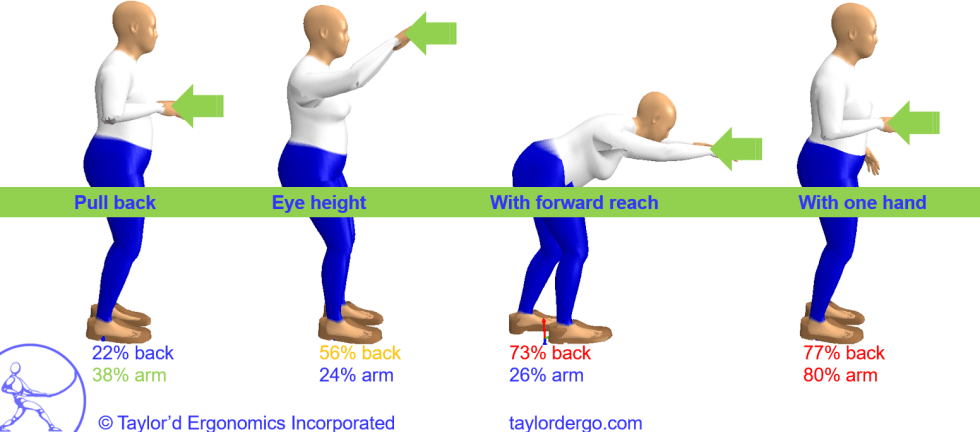

As an example, working on utility meters can require service reps to use awkward postures, because meters may be too high or too low for ideal force generation. The first two images above compare effort, expressed as a percentage of maximum strength for a worker. (See below for methods. A higher number means a more difficult task.) The first image shows the effort required to pull back with 20 lb of force on a wrench, at waist height. The second shows the effort required to exert that same effort at eye height. When a force is exerted at a height that is not efficient for the muscles, they have to work harder. Even more confounding, the ideal height for various force directions is different – for example, we would prefer a low height for pushing down so we can use body weight, but that same height for pushing forward would be difficult.

What’s the best height?

You can appreciate that utility companies would be challenged to select the perfect height for a meter, as service reps can be very tall or very small. This is true for work in all sectors. I’ve been saying for decades that, in the future, I imagine that workers will enter their workstations, press a button, and be adjusted to their ideal working height. (We’ve actually achieved that vision with some of our clients!)

Forward reach

Forward reach can also affect a worker’s posture. Let’s continue to consider the utility service worker’s job. There may be obstacles around the meter – many people plant gardens around their homes, and these can limit where the worker can step. The third image above represents the amount of effort required to apply that 20 lb pull force with the feet about a yard away from the meter. The “reach” effect is even more pronounced for forces applied vertically and sideways, where arm strength is more limiting.

Grip

“Posture” can also include grip. A worker has the best strength when using a power grip – the hand wraps fully around the object. When pulling on a wrench, a power grip allows the worker to transfer the pulling effort from the legs, back, and arms, through the hands to the wrench. At high efforts with a power grip, grip strength is rarely what limits the worker. Now imagine the worker can only use one hand instead of two, as shown in the fourth image. Other examples of tasks where grip might limit ability would pulling on the corner of a box instead of a handle, or pulling a cut-out handle or a banding strap. When the grip is impaired, the worker needs to use more effort, and grip strength can be limiting.

What else can constrain body position?

Posture can be constrained by many other factors: head clearance, object dimensions, slippery or awkward footing, unbalanced loads, and more. Ergonomists consider all of these factors when assessing a job, so we can provide recommendations that will mitigate risk by optimizing a worker’s ability to generate effort.

Does a worker have control over posture?

Common knowledge dictates that we should “sit up straight” and “lift with our legs”. Do these postural references have value? Certainly, workers can improve their risk of injury by heeding these tips; a squat lift is almost always stronger than a stoop lift. But in many cases, work design drives posture. The worker sits slouched because the screen is too low, or lifts with the back rounded to remove an item from a waist-high bin.

Can the new automated assessment tools capture all this?

Many apps are coming onto the market that speed up the process of identifying awkward back and arm postures, and that’s pretty exciting because manually tracking this data is time consuming. Last week, I talked about force direction. To assess the risk of injury on a job, we must measure the force, and understand the direction of that force. I have not seen a system that helps us to efficiently measure force, or its direction, and this is a critical part of risk assessment. I haven’t seen one that integrates grip data either. If you are using an automated system to assess a job, forces must still be measured in the workplace, and that data needs to be paired up with the postural data.

At Taylor’d Ergo, when we assess a job, we measure forces with a gauge, we measure hand positions, and we use that data and photographs to replicate postures in our biomechanical models. We also measure frequency and duration of efforts, using a good old stopwatch. Next week, I’ll talk about how frequency and duration affect risk.

Notes about my methods: To report efforts as a percentage of strength, I evaluated the demands on an average-height, average-weight, 25th percentile female worker (weaker than 75% of other females). We traditionally think that, if this worker can do the job, more than 75% of all workers are safe. I used University of Michigan’s 3D Static Strength Prediction program, and LaDelfa and Potvin’s Arm Force Field models to calculate strength. The images above all represent the effort required for this worker to exert 20 lbs of pull force.