When you see a worker pushing, pulling, or lifting a load, you might wonder how much effort they are using. As an ergonomist in a workplace, we are usually compelled to measure that force. We can use a force gauge to measure the weights and push/pull forces required on the job.

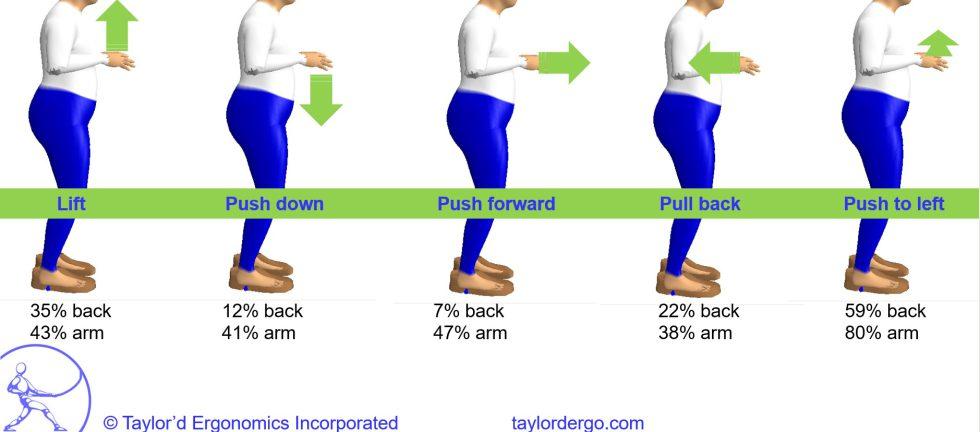

You might also think about the effect of that force on the worker’s body. A given force, say 20 lbs, might be easy to exert in one direction, and harder in another. When we assess the risk of injury on a job, we need to understand not only the amount of force, but the direction of that force. In the image above, I’ve shown the effect of a 20 lb force on a “small” worker, in various directions. The numbers below each mannequin represent the percentage of maximum strength.

I used biomechanical models to calculate these percentages. (University of Michigan’s 3D Static Strength Prediction Program, and LaDelfa and Potvin’s Arm Force Field.) I used 50th percentile female height and weight, and 25th percentile strength. I used the same posture for all 5 analyses, and assumed that each hand would contribute 10 lbs of force.

You’re probably wondering, “What do these numbers mean?” A higher number means that the worker is using more effort – the demands are closer to the workers maximum capacity. So, the same amount of “weight” or “force” can take more effort for the worker, depending on which direction the force must be moved.

- When the worker “lifts” 20 lbs, the load on the back is about 35% of the worker’s maximum strength, and 43% of the worker’s maximum arm strength.

- Pushing down with 20 lbs of force requires much less effort for the back, but not much less for the arms.

- The direction of the force seems to affect the back more than the arms, when pushing forward, back, up and down.

- Pushing sideways with 20 lbs of force requires the highest effort of all, for the back (twisting) and arms! Keep a lookout for forces that are exerted sideways!

Why is this important?

- If the ergonomist doesn’t measure the force in the direction that it is applied, the analysis won’t truly reflect the job demands.

- If the assessment doesn’t account for the direction of the force, then it won’t account for the fact that workers have more strength in some directions than others. This is why we can’t give one number when we are asked, “How much force is acceptable?” It’s also why we use a biomechanical model instead of a chart, when forces are applied in unusual directions.

- And, of course, if workers have a choice, they should choose the direction that gives them the greatest strength. If the worker can turn to face the direction of the force, the twisting and arm efforts can be reduced.

When you ask ergonomists to assess a job, you should expect them to measure the force required, and to interpret it with respect to the posture used and the frequency and duration of the task.

Next week, I’ll talk about how posture affects strength. And later, I’ll talk about how frequency and duration interact with these forces.