It might surprise you to learn that most of our clients have full-time safety coordinators. And yet, when you look at job postings for safety positions, many of them identify “ergonomics” as one of the job responsibilities. Given that strain/sprain injuries account for the majority of incidents and the majority of WSIB costs, you’d think that “safety” should be very much about ergonomics. So why would an organization with a safety department need to hire ergonomists?

1. Safety education focuses on the “life-threatening” and legislated hazards. If you look up college safety programs, you’ll find that they include, at most, one mandatory course in ergonomics. I looked up three:

-

- At Fanshawe College, the OHS program includes 13 mandatory courses, including 1 in ergonomics. This course provides “basic knowledge of ergonomics and musculoskeletal injuries…..Students also learn about the role of an ergonomist within the occupational health and safety team.”

- Mohawk’s program includes 1 ergo course amongst the 8 mandatory courses, also billed as an “introduction to the science”.

- Ryerson’s degree program includes one mandatory ergonomics course in 4 years.

Even in the JHSC certification training (5 days total), strain/sprain injury prevention is included only in Part II, and only if strain/sprains are identified as one of 6 relevant hazards in the participant’s workplace.

Ergonomics certification, by contrast, includes at least 100 hours of ergonomics instruction, plus 700 more in the supporting sciences of anatomy, biomechanics, physiology, etc. Fanshawe’s Advanced Ergo program, for example, includes 8 courses on ergonomics, and one on safety. Most ergonomists won’t claim to be specialists when it comes to more traditional safety hazards; ergonomics students get roughly the same exposure to safety as safety students get to ergonomics.

2. Most organizations are very focused on compliance issues. A majority of the safety professional’s time is consumed with incident investigation and compliance surrounding cuts, chemicals, PPE, noise, and other green book issues. Even when the safety professional has an ergonomics background, relatively little time gets spent on ergo issues.

We recently surveyed graduates of Fanshawe’s ergonomics program to see what types of jobs they had, and how they spent their time. Of the 14 people who responded to the survey, only half had “ergonomics” or “human factors” in their job title. 70% reported that musculoskeletal injuries were one of the top three injury causes (surprisingly low, actually). And 8/14 reported that the majority of their projects were “ergonomics”.

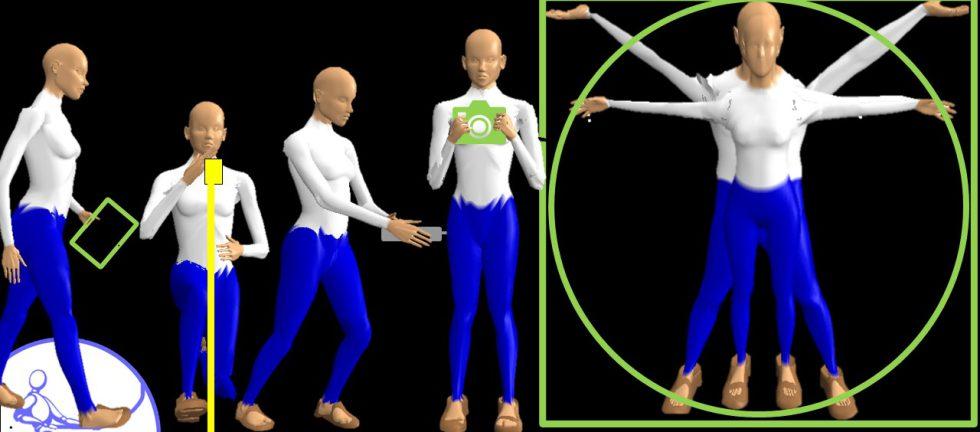

3. Safety professionals rarely have access to ergonomics assessment tools. When a safety manager asks for “tools”, they typically focus on devices that will support compliance issues: devices to measure noise, heat, chemicals. They rarely request the types of tools that ergonomists need to do their job well: biomechanics software, force dynamometers, grip and pinch gauges, etc. When ergonomists graduate, they may have some classroom and lab experience with these tools, but, as with any skill, if you don’t use it, you lose it. Pen and paper assessment tools (RULA, Liberty Mutual tables, NIOSH equation) that use only a tape measure and weigh scale can be used to identify high-risk tasks, but they are not usually sensitive enough to help a company evaluate various alternative solutions the way a biomechanics analysis can. Our survey suggested that only 6 of the 14 respondents were using biomechanical analysis software.

4. It’s about time. I mean, it’s about how time is spent…..safety coordinators have a lot of legislation–driven tasks. They have to ensure that MSDSs are current, that LOTO training and programs are current, that designated substances are handled and documented properly, and more. Because no one dies from strain/sprain injury and fines for ergonomics-related issues are rare, these initiatives get pushed to the bottom of the priority list. In our survey, only 35% of respondents reported spending more than half of their day on ergonomics (and that includes the 50% who had ergonomics in their job titles!)

5. And also, ergonomics hazards are hard to fix. Most people walk by strain/sprain injury hazards every single day. Many workers experience discomfort every hour of every day. And yet the solution to these issues is often elusive. Ergonomics requires a dedicated effort to focus on and evaluate these hazards, gather information from stakeholders to root out potential solutions, quantitatively compare alternatives, and then lead the implementation process through mock-ups, trials, purchases or workstation modifications, and employee training. An ergonomist can focus singularly on these initiatives, in a way that safety professionals rarely have the opportunity.

If your management team thinks that the safety department is equipped to handle ergonomics, maybe they should read these bits of feedback from our clients, who have full-time safety professionals on-site:

- “Having an on-site resource is a welcome support for an HSE professional….from completing an office assessment, to reviewing a challenging repetitive motion task. There are many ways to view corrective actions; an ergonomist’s eye brings a great deal of value.”

- “Employees see that the company is putting forth their best efforts to ensure their health and safety, which increases employee morale.”

- “Carrie at Taylor’d Ergonomics has been very accommodating, professional and insightful! I would recommend Taylor’d to help with your ergonomics assessments.”

- “Highly reliable, great work and very recommended. We have had excellent training and services from Taylor’d Ergonomics.”

A safety professional can leverage the ergonomist’s skills, tools, and focused energy. If your organization doesn’t need a full-time ergonomist, but strains and sprains are one of your top three hazards, call us. We’ve been looking for you. (519)623-7733.