Health and safety professionals and ergonomists know that administrative controls are an essential part of hazard control in the workplace. However, relying solely on administrative controls can be costly and ineffective in the long run. We need to prioritize engineering controls. And when admin controls are required, I’d argue that we should try to “engineer” them to make them more effective.

What are administrative and engineering controls?

Let’s first define administrative controls. These are procedures or policies that aim to minimize exposure to hazards in the workplace. Examples in the ergonomics world include job rotation, lifting training, or identifying and encouraging the use of best practices. On the other hand, engineering controls eliminate or control hazards before the worker is exposed to them, such as hoists, lift tables, diverters, and lighter or better-designed tools.

The Real Cost of Administrative Controls

While administrative controls may seem cheaper to implement, we need to consider the labour costs associated with them. For instance, providing hazard-specific training requires collection of workplace examples, identification of best practices, and development and implementation of hands-on practical training for all workers. Finding a second worker to help lift a heavy load or providing additional relief can add up to significant labour costs. Moreover, the pressure to meet production goals may lead workers to bypass administrative controls, which puts them at risk of injury.

For example, if we ask a worker to take four steps around a pallet for half of the boxes on the pallet, and the job involves manually lifting two boxes per minute, those four steps might add up to 30 minutes per day of extra walking. Every shift. What is the labor cost of this time? Wouldn’t the time be better spent on value-added work? Perhaps this worker could also apply a label, or complete another subassembly.

“Engineering” Administrative Controls

If it’s truly not possible to engineer a control, perhaps “not now” or “not yet”, how could we “engineer” an administrative control? We can engineer some administrative controls to prevent workers from performing a job without the administrative control in place. For instance, if the job involves reaching upline to retrieve parts, we can engineer a control by putting a barrier up that prevents the worker from reaching up the line. This prevents workers from bypassing administrative controls and keeps them safer. It might not have been the full engineering control that we wished for, but it’s more effective than putting up a sign advising workers not to reach.

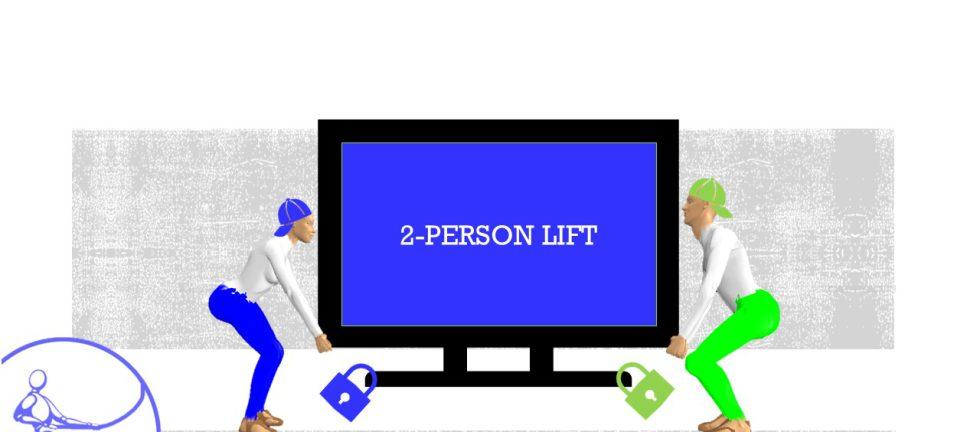

To further illustrate, consider the example of workers who might lift big, heavy, awkward loads all by themselves, despite a two-person lift policy. Pressure to “get the job done” or “provide excellent customer service” often leads workers to bypass administrative controls, with supervisors looking the other way. If the organization accepts that the solution to a lifting hazard is an admin control (2-person lift policy), then it must bear the cost of that solution: when the heavy load needs to be lifted, the worker will have to take the time to hunt down a second person, taking that person away from another process. If we’re serious about safety, why don’t we prevent people from lifting heavy, awkward loads with the same diligence as we apply to Lockout/Tagout, which prevents workers from being injured while fixing equipment?

Conclusion

As health and safety professionals, our goal is to ensure that our workers stay safe and healthy, and “engineering” our administrative controls can help us achieve that. While administrative controls have their place in hazard control measures, we need to carefully consider the long-term costs and effectiveness. Sometimes, a careful accounting of the real costs of an admin control can show that the engineering control was not as expensive as we thought. And when the ideal engineering control measure is not in the budget right now, perhaps there’s a way to “engineer” the admin control, making it harder to bypass your admin control measures.

Need some help to identify and implement effective control measures? Consider bringing one of our ergonomists on-site one day per week, to guide your ergonomics program. Check out our “on-site ergo” program, or contact info@taylordergo.com to set up a meeting to discuss your needs.

P.S. The image with this blog was intended to be funny. I don’t propose locking down the family TV to ensure that burglars come in pairs. And even two people couldn’t lift while it was locked!