Most companies provide “hazard-specific” training for employees assigned to heavy jobs. Federally-regulated employers are required to do this, according to Section 14 of the Canada Occupational Health and Safety Regulations, part of the Canada Labour Code. Provincially-regulated companies have a more general duty to ensure that “lifting, carrying or moving of the material, articles or things does not endanger the safety of any worker” under the Ontario Industrial Regulations (Section 45).

Is your ergonomics training “hazard-specific”?

What does your strain/sprain injury prevention training look like? Is it truly “hazard-specific”? For example, if the hazard is a requirement to move a really heavy, large box without handles, does the training actually focus on how to do this task safely?

Once upon a time, I hated training. I dreaded standing at the front of a dimly lit room, presenting slide after slide, watching people doze off and then jerk their heads up every few minutes. That was then. This is now. Training is engaging! Training is hands-on! Training is about games and experiments, and contests! Training includes lots of “ahah” moments, when participants understand something new and recognize how it applies to them.

To create hazard-specific training, we need to truly understand the demands of the job, and the work practices that we want to promote. Our ergonomists have a process for this, which we call “best practice studies”.

What is a best practice study?

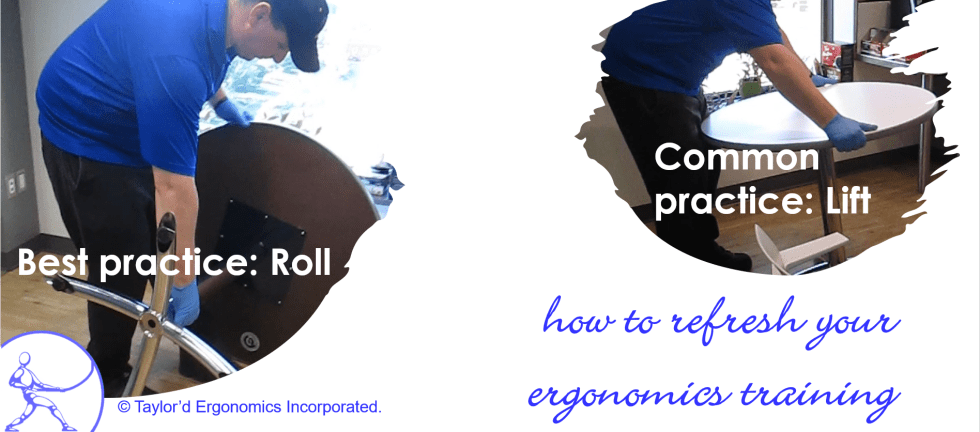

An ergonomist works with a small group of experienced employees to understand a task, and to measure the efforts associated with the common and best practices for that task. “Common practices” are methods that are often used by less experienced workers, or workers who were not provided with any biomechanics training. If you or I walked into the workplace without any understanding of the hazards, we would likely use the “common practice”. A “best practice”, by comparison, offers some ergonomic advantage. It might be as simple as knowing how you position your feet, or it might involve a more complicated leverage or diverting technique. The ergonomist’s goal is to compare the biomechanics of these practices, so we can create content that shows what to do instead of the “common” approach.

The output of a best practice study is a poster-like page that clearly shows the common and best practice, and how the best practice is better, biomechanically. It’s not a risk assessment; we don’t tell you that the task is “bad”, and we don’t provide recommended control measures. (If hazards or solutions jump out at us, we’ll mention them to you privately, and we are always happy to do risk assessments if you ask us!) Once we have a dozen or so of these practices, creating hazard-specific training simply involves figuring out how to get participants to experience the difference, in a teaching setting, and receive feedback when they get it right.

Is your ergonomics training engaging?

If your ergonomics training is as stale as the bread at the back of the fridge, you can put a new spin on it. Think about what people need to learn to do, and then find a way to show them, and let them try it, in a safe environment. Other ideas to refresh your ergo training:

– Can you use tech to reinforce the habits you’re teaching?

– Can you “gamify” the exercise?

– Can you use video so workers can “see” themselves?

– Can you partner people so they can provide feedback to each other, carrying the learning into the workplace?

In today’s workplace, there’s no reason that training needs to be dull. Contact us for help!