How the elimination of “waste” from production is increasing the risk of musculoskeletal disorders (MSDs) amongst workers.

by Karen Hoodless

I recently attended a webinar given by Dr. Patrick Neumann (Associate Professor in the Mechanical and Industrial Engineering Department at Ryerson University), where he “Exposes the link between MSDs and Lean Production.”

Most people have heard of “lean” production: a process that looks at “wasteful” activities that decrease productivity. This term was formally introduced to the world in 1990 by James P. Womack in his book “The Machine that Changed the World”, where he described how Toyota moved from mass production to lean production using 8 guiding principles. Yes, you heard that right – 8 guiding principles. Most industries latched onto minimising waste with 7 principles, addressing:

- – overproduction

- – wait times

- – unnecessary transport (handling)

- – over-processing (quality)

- – excess inventory

- – unnecessary movements, and

- – defects

The eighth principle described in the Toyota Production System is unused employee creativity. In other words, companies should solicit employee input, in order to improve jobs. Employees are a key resource for identifying inefficiencies and improving productivity, quality and comfort. (Ergonomists have been tapping into this resource for years.) However, Dr. Neumann reports that ignoring the “8th” waste has an overall effect on worker health.

The association between lean production and increased MSDs has been reported as far back as 1993 (Berrgren 1993; Landsbergis et al., 1999; Wesgaard & Winkel, 2011), with lost-times rates increasing almost 3 times following implementation of the lean process. As work pace intensified, lean also negatively affected workplace commitment, self-efficacy, job breadth, and job satisfaction (Parker 2003; Jackson & Martin, 1996).

Dr. Neumann provided an example that showed how lean might cause an increase in MSD risk. First, he quantified the workload, and categorized each task as:

- value-added (direct work processes)

- non-value added-but necessary (material and tool handling), or

- “disturbances” (non value-added waste, such as waiting or pausing).

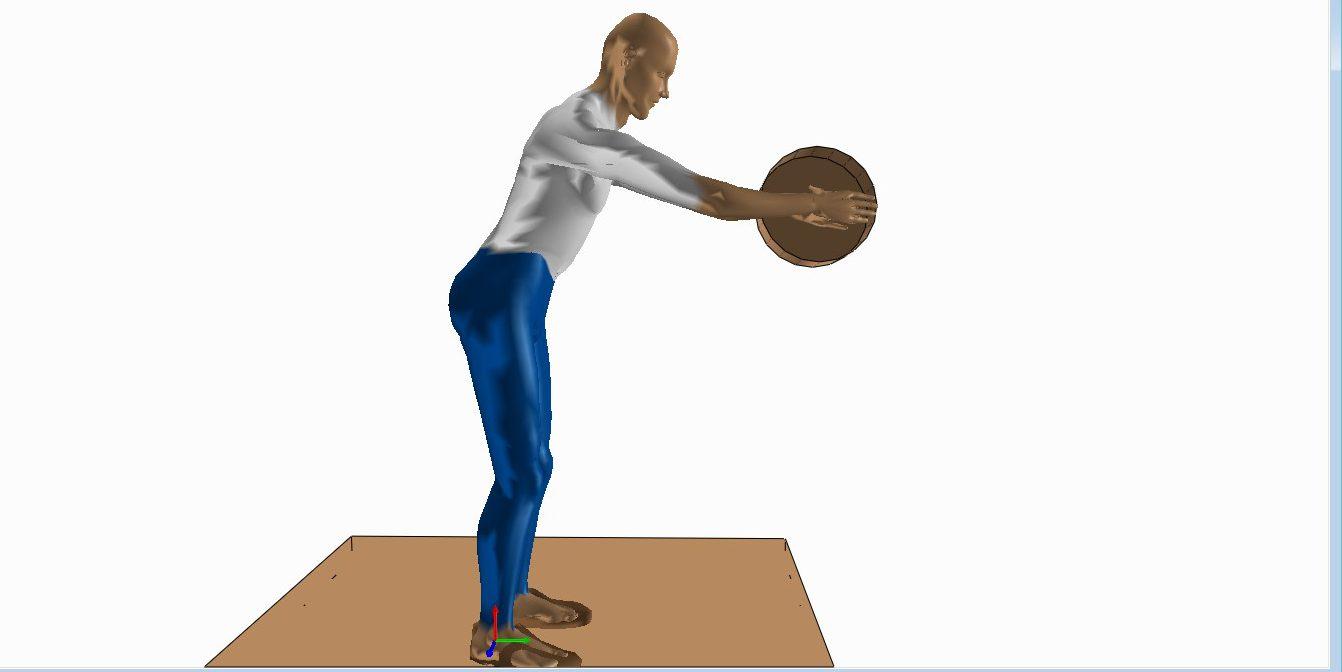

He simulated removing the “waste” from a car disassembly task. Removing the time allocated to “waste” increased the time allocated to direct and indirect work activities. In other words, the job became more “repetitive”, and time spent in awkward postures increased, with less time for muscle recovery. His study validated previous research done at an engine assembly job (Palmerud et. al., 2012).

In 2001, Toyota’s President Mr. Cho, admitted that: “Eliminating waste is just one third of the equation of making production successful. Eliminating overburden to people and equipment is just as important…” MSD risk increases when a company strictly focuses on eliminating waste. Engineers, managers, and lean practitioners need to consider the work that remains, when the rest is removed. What impact will increased exposure to these tasks have on the worker? This is where an ergonomist can help.

An ergonomist can evaluate the cumulative demands (risk) associated with the current, and the proposed job. If you reduce the waste, will the employee have enough muscle recovery time to avoid injury? If the proposed job will create a high risk, the ergonomist can look for other changes that would off-set the lost muscle recovery time.

For example:

- an engineer determines that an operator has enough time available between parts to do some subassembly work.

- the ergonomist finds that adding these tasks removes too much recovery time, increasing the risk of injury. Her assessment shows that the high risk is caused by a long forward reach to place a heavy part on a conveyor. This task demands a lot of muscle recovery time.

- the ergonomist finds that reducing the forward reach could reduce the employee’s need for muscle recovery, enough to safely allow the addition of the subassembly tasks. (A nice, happily-ever-after story!)

Neumann suggested the following countermeasures to lean production:

- innovation (using technology to eliminate job hazards)

- job enlargement (provided that it there is variety of job demands allowing for muscle recovery), and

- changing the job design and development process to include ergonomics.

We at Taylor’d Ergonomics couldn’t agree more.

Need some help keeping MSDs in check as you ramp up your Lean initiatives? Give us a call 519-623-7733, or carrie@taylordergo.com.