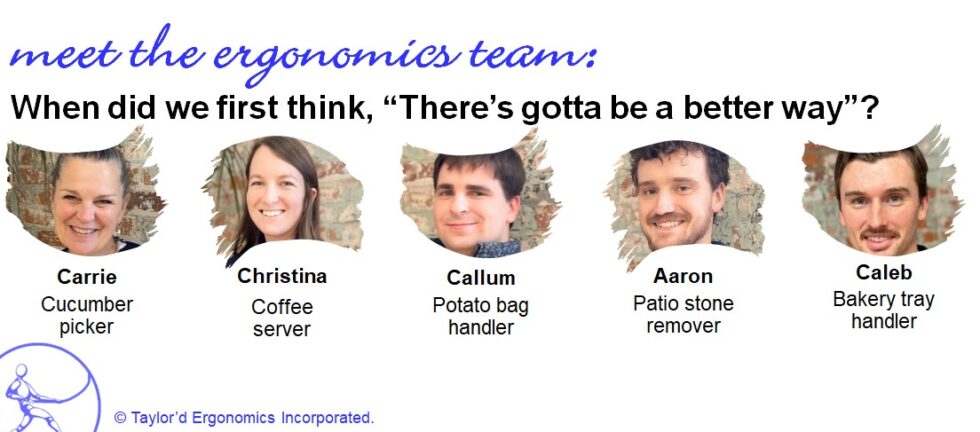

We thought it might be interesting to share our team member’s motivations for getting into the field of ergonomics.

Carrie

Why ergo? I’ve long held the idea that most ergonomists start into their career inspired to make the work world a better place for people like themselves. I represent roughly the “25th percentile” profile: I’m shorter-than-average, and I have less-than-average strength. If more jobs were designed so that I could do them, most people, who are bigger and stronger than me, would be able to do them with ease.

I didn’t hear about ergonomics until my third year of my kinesiology degree, but I was excited at the prospect of combining my science education (by analyzing work) with my creative mindset (by solving problems).

First “there’s gotta be a better way” moment: I also believe that most ergonomists had a moment, early in their work lives, when they declared, “There’s got to be a better way.” For me, that happened in my first job, picking cucumbers for a local market gardener. If you’ve ever seen this job, you’ll understand why a teenaged cucumber picker might aspire to become an ergonomist. (Never mind that I had no idea what an ergonomist was at the time.)

- A vehicle with low seats carries 6 pickers over the rows.

- Each picker places the feet on either side of a basket, and works between the legs, shoving leaves aside, harvesting ripe cucumbers, and placing them in the basket.

- You don’t want to miss any ripe cucumbers; the next time you pick that row, you’ll have to pick the oversized cukes, but they’ll be removed from the hampers before you get paid.

- I picked 5-7 hampers per day, and I earned $0.75/hamper. A great lesson in hard work!

At our team meeting on Friday, I asked our team members what inspired them to get into ergonomics, and this is what I learned:

Christina

Why ergo? I had a job during university in an auto assembly plant, which was very physically demanding. I wanted to help people to work without injury.

First “there’s gotta be a better way” moment: One of my first jobs was serving coffee, where I quickly realized that handling a full pot of hot coffee above my shoulder height was a recipe for disaster.

Callum

Why ergo? I’ve always enjoyed learning how things work and how things break, and people are interesting examples of both.

First, “there’s gotta be a better way” moment: I worked in the basement of a restaurant, handling 50 lb bags of potatoes. (‘Nuff said.)

Aaron

Why ergo? I like to understand how things are made, and jobs associated with the process. Being an ergonomist allows me to use my understanding of body mechanics, and my interest in problem solving.

First, “there’s gotta be a better way” moment: When working as a landscaper, one of my jobs was removing damaged bricks from patios. Usually, we’d have to use our fingers and screwdrivers to pry the bricks out, or break them. While I was working there, a solution was implemented: a vacuum lifter now removes the damaged bricks. It saved our fingers and backs, and inspired me on my path to becoming an ergonomist.

Caleb

Why ergo? I’ve always enjoyed the problem-solving process, and working in a team to come up with a solution. Ergonomics allows me to work with other ergonomists, but also with a multidisciplinary bunch of people – workers, supervisors, safety folks, engineers, maintenance, and more.

First, “there’s gotta be a better way” moment: One of my first jobs was in a commercial bakery, where I lifted trays of bread from one conveyor to another, for 12-hour shifts. I look forward to the opportunity to make jobs like this less demanding, so people can go home at the end of the day without the aches that I experience.

So, my hypothesis that we get into ergo because we are particularly large or small might not have played out here, but it may be worth mentioning that we purchase very few size “medium” uniforms. 😊

FAQs

- What qualifications or education are needed to become an ergonomist?

Ergonomists typically have a background in fields like kinesiology, engineering, or industrial design. Many also pursue specialized training in ergonomics or occupational health and safety to gain expertise in human-centered design principles. For more information about Canadian Certification, please visit cccpe.ca.

- How does ergonomics improve productivity in the workplace?

By optimizing workspaces and tasks to fit the needs and capabilities of workers, ergonomics reduces fatigue and injury, leading to fewer sick days and greater efficiency. Employees are able to work more comfortably, which results in increased output and better overall performance.

- Can ergonomics be applied to all industries?

Yes, ergonomics can be applied across various industries, including manufacturing, healthcare, office work, agriculture, and more. Any job that involves physical labour or repetitive tasks can benefit from ergonomics principles to improve worker safety and comfort.